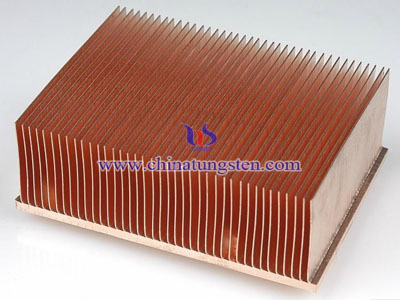

Tungsten Copper Heat Base

Introduction

Tungsten copper heat base also called tungsten copper heat sink. Tungsten copper heat base is a heat base which is made of tungsten copper alloy. A heat base is a term for a component or assembly that transfers heat generated within a solid material to a fluid medium, such as air or a liquid. Examples of heat bases are the heat exchangers used in refrigeration and air conditioning systems and the radiator (also a heat exchanger) in a car. Heat bases also help to cool electronic and optoelectronic devices, such as higher-power lasers and light emitting diodes (LEDs).

A heat base is physically designed to increase the surface area in contact with the cooling fluid surrounding it, such as the air. Approach air velocity, choice of material, fin (or other protrusion) design and surface treatment are some of the design factors which influence the thermal resistance, i.e. thermal performance, of a heat base. One engineering application of heat bases is in the thermal management of electronics, often computer central processing unit (CPU) or graphics processors. For these, heat base attachment methods and thermal interface materials also influence the eventual junction or die temperature of the processor(s). Thermal adhesive (also known as thermal grease) is added to the base of the heat base to help its thermal performance. Theoretical, experimental and numerical methods can be used to determine a heat base's thermal performance.

Tungsten copper heat base material is a composite of tungsten and copper. W-Cu material with both tungsten low expansion characteristics, but also has copper of high thermal conductivity properties, and the tungsten and copper in the thermal expansion coefficient and thermal conductivity can adjust the W-Cu composition and to design (with professional terms, tungsten and copper in the performance can be cut, and thus the application to the tungsten and copper brought great convenience.