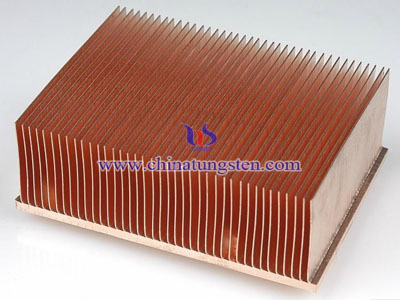

Copper Molybdenum Heat Base

Copper molybdenum heat base is fabricated from carefully controlled porous Molybdenum that is vacuum infiltrated with molten copper. This results in a MoCu composite that has high conductivity and a matched low thermal expansion for heat bases.

Molybdenum copper has property of high electrical and thermal conductivity. Molybdenum is a better element for electricity conductivity except for gold, silver and copper in the metals. Therefore, molybdenum-copper alloy composed by molybdenum and copper have very high electrical and thermal conductivity. PA&E offers engineers the option of using integrated molybdenum/copper heat bases and now, for applications where weight is a primary consideration, the company is offering an aluminum silicon carbide heat base option.

Copper molybdenum heat base is a composite made from Mo and Cu, Similar to W-Cu, CTE of Mo-Cu can also be tailored by adjusting the composition. But Mo Cu is much lighter than W-Cu, so that it is more suitable for aeronautic and astronautic applications.

Our molybdenum copper composites to be used extensively in thermal mounting plates, chip carriers, flanges, and frames for high-powered electronic devices. With the thermal advantages of copper with the very low expansion characteristics of molybdenum, molybdenum copper has properties similar to those of silicone carbide, aluminum oxide, and beryllium oxide. The thermal conductivity and low expansion also make molybdenum copper alloy an excellent choice even for extremely dense circuits.

Advantages: High thermal conductivity, Excellent hermetic, Excellent size control, surface finish and flatness, Semi-finished or finished (Ni/Au plated) products available.

| Composition (Wt%) | Mo 85% Cu 15% | Mo 70% Cu 30% | Mo60% Cu 40% | Mo 50%Cu 50% |

| Density(g/cm3) | 10.0 | 9.6 | 9.66 | 9.4 |

| Coefficient of Thermal Expansion (10-6/K) | 6.3 | 7.5 | 8.7 | 9.8 |

| Thermal Conductivity(W/mK) | 160 | 190 | 220 | 245 |

| Specific Heat Capacity(J/kgK) | 275 | 300 | 310 | 320 |

| Specific Electrical Resistance(uΩm) | 0.044 | 0.035 | 0.031 | 0.027 |

| Vickers Hardness(HV10) | 235 | 175 | 160 | 145 |